Phone:

+86-18915806777

+86-0564-5176999

| Test item | Test accuracy (Manufacturer) | As-Measured (For Reference) |

| Roundness | 1.0μm(2.0μm*1) | 0.5μm |

| Cylindricity | 2.0μm | 0.85μm |

| Coaxiality | 2.0μm | 1.0μm |

| Roughness | Ra0.20μm | Ra0.17μm |

| Verticality | 2.0μm | 0.18μm |

| X-Axis (Ref. Measured Data) | Z-Axis (Ref. Measured Data) | |

| Positioning Accuracy | 3.45.0μm | 2.75μm |

| Positioning Repeatability | 2.65μm | 2.22μm |

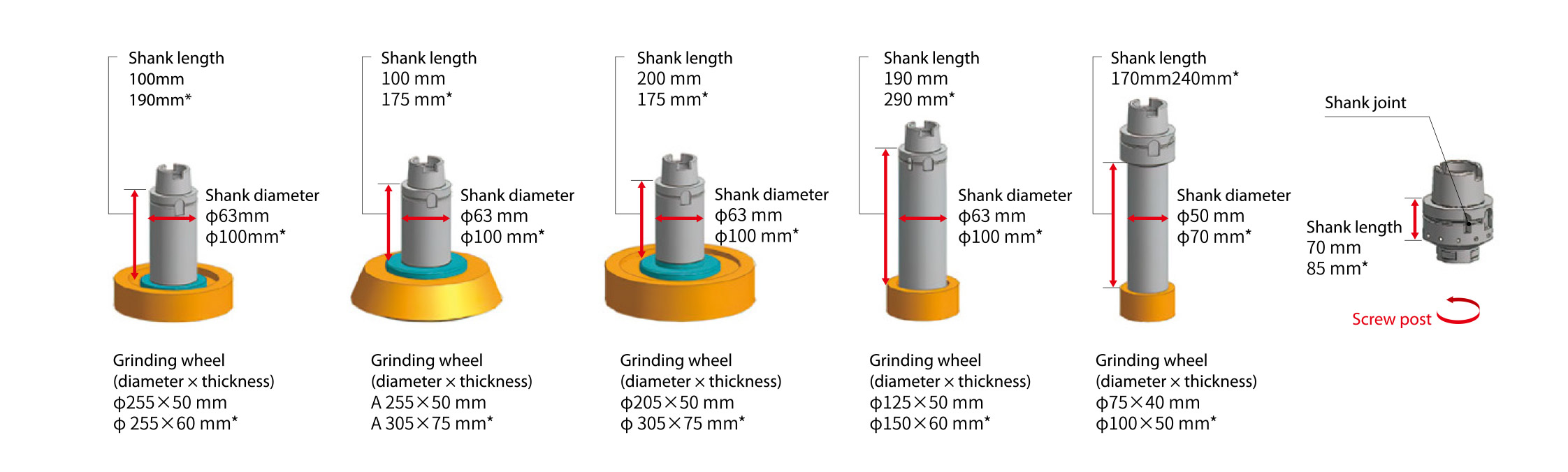

Vertical Compound Grinding Machine 55/85/125( The following 6 types of accessory tools are available)

The grinding wheel with maximum diameter of p 255 mm ( 305 mm) can be stored in the ATC unit. However, the size of adjacent toolshould be limited to A 180 mm or less.

*Vertical Compound Grinding Machine 85/125